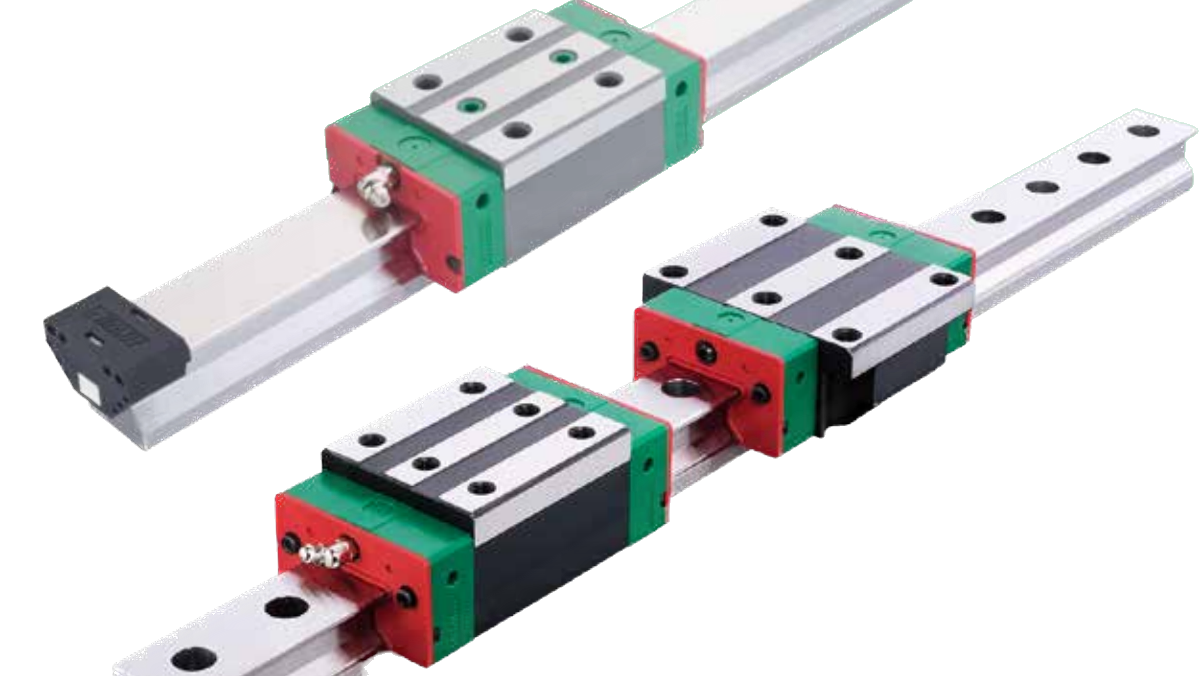

Everything You Need to Know About Linear Guide Rails: A Customer's Guide to Smooth & Accurate Motion In today's high-precision world, Linear Guide Rails are essential for machines that demand smooth, accurate, and repeatable motion. Whether you're into CNC machining, automation, 3D printing, or mechanical engineering, understanding how these systems work and choosing the right one can make all the difference. What is a Linear Guide Rail? A linear guide rail, also known as a linear motion guide, is a mechanical component that allows for precise linear movement in one direction. The system consists of a linear rail track and linear guide block (or carriage) that moves smoothly along the rail, typically using ball bearings or rollers. These systems reduce friction and enable controlled motion, which is why they're used in everything from industrial robots to CNC machines and medical equipment. Key Components of a Linear Rail System Linear Rail Track A hardened, precision-machined track that supports and guides the carriage. Linear Guide Block (Carriage) Ball bearings or rollers usually support the moving part that glides along the rail. Linear Bearings These ensure smooth, low-friction movement of the carriage across the rail. Top Applications for Linear Guide Rails CNC Machines: Provides precise and stable cutting, milling, and engraving motion. 3D Printers: Ensures accurate layering and axis movement. Industrial Automation: Used in robotic arms, conveyors, and pick-and-place machines. Medical Devices: Enables quiet, vibration-free, and precise movement. Benefits of Using Linear Slide Rails High Accuracy & Repeatability Low Friction for Smooth Operation Durability and Long Service Life Load-bearing Capacity Compact & Space-saving Design Choosing the Right Linear Guide System When selecting a Precision Linear Guide, consider the following: Load Capacity: How much weight does it need to support? Speed Requirements: Higher speed may require low-friction and high-durability options. Environment: Dust, heat, or moisture exposure requires sealed or corrosion-resistant models. Mounting Space: Choose a size that fits your machine’s footprint. 🔍 Related Terms and Popular Searches If you're shopping online or doing research, keep an eye out for related terms: Linear Bearing Rail CNC Linear Rails High Precision Linear Motion Guide Heavy-duty Linear Slide System Linear Motion Track 🛒 Where to Buy Linear Guide Rails? Look for reputable dealers and brands that offer: Genuine Products Engineering Support Custom Lengths & Sizes Fast Shipping & Stock Availability Check out suppliers with a proven track record in precision mechanical components and industrial automation. Final Thoughts A linear guide rail system is more than just a mechanical component—it’s the backbone of precision movement in modern engineering. Whether building a CNC machine or upgrading factory automation, investing in the right linear rail system can save time, increase accuracy, and boost productivity.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Everything You Need to Know About Linear Guide ...

2025-04-09T02:15:29

Everything You Need to Know About Linear Guide Rails: A Customer's Guide to Smooth & Accurate Motion In today's high-precision world, Linear Guide Rails are essential for machines that demand smooth, accurate, and repeatable motion. Whether you're into CNC machining, automation, 3D printing, or mechanical engineering, understanding how these systems work and choosing the right one can make all the difference. What is a Linear Guide Rail? A linear guide rail, also known as a linear motion guide, is a mechanical component that allows for precise linear movement in one direction. The system consists of a linear rail track and linear guide block (or carriage) that moves smoothly along the rail, typically using ball bearings or rollers. These systems reduce friction and enable controlled motion, which is why they're used in everything from industrial robots to CNC machines and medical equipment. Key Components of a Linear Rail System Linear Rail Track A hardened, precision-machined track that supports and guides the carriage. Linear Guide Block (Carriage) Ball bearings or rollers usually support the moving part that glides along the rail. Linear Bearings These ensure smooth, low-friction movement of the carriage across the rail. Top Applications for Linear Guide Rails CNC Machines: Provides precise and stable cutting, milling, and engraving motion. 3D Printers: Ensures accurate layering and axis movement. Industrial Automation: Used in robotic arms, conveyors, and pick-and-place machines. Medical Devices: Enables quiet, vibration-free, and precise movement. Benefits of Using Linear Slide Rails High Accuracy & Repeatability Low Friction for Smooth Operation Durability and Long Service Life Load-bearing Capacity Compact & Space-saving Design Choosing the Right Linear Guide System When selecting a Precision Linear Guide, consider the following: Load Capacity: How much weight does it need to support? Speed Requirements: Higher speed may require low-friction and high-durability options. Environment: Dust, heat, or moisture exposure requires sealed or corrosion-resistant models. Mounting Space: Choose a size that fits your machine’s footprint. 🔍 Related Terms and Popular Searches If you're shopping online or doing research, keep an eye out for related terms: Linear Bearing Rail CNC Linear Rails High Precision Linear Motion Guide Heavy-duty Linear Slide System Linear Motion Track 🛒 Where to Buy Linear Guide Rails? Look for reputable dealers and brands that offer: Genuine Products Engineering Support Custom Lengths & Sizes Fast Shipping & Stock Availability Check out suppliers with a proven track record in precision mechanical components and industrial automation. Final Thoughts A linear guide rail system is more than just a mechanical component—it’s the backbone of precision movement in modern engineering. Whether building a CNC machine or upgrading factory automation, investing in the right linear rail system can save time, increase accuracy, and boost productivity.

2025-04-09T02:15:29

Keywords

- cnc machines

- boost productivity

- cnc machine

- reputable dealers

- popular searches

- require lowfriction

- load capacity

- moving part

- industrial robots

- moves smoothly

- modern engineering

- mechanical componentits

- ball bearings

- mechanical component

- systems work

- system consists

- repeatable motion

- rail typically

- customers guide

- precision movement

- youre shopping online

- precise movement benefits

- precise linear movement

- mechanical engineering understanding

- precision mechanical components

- rail linear bearings

- systems reduce friction

- linear rail system

- precision linear guide

- linear guide system

- linear motion guide

- linear guide rail

- enable controlled motion

- smooth accurate motion

- rail top applications

- linear rail track

- linear guide block

- linear guide rails

- proven track record

- smooth operation durability

- robotic arms conveyors

- stable cutting milling

- hardened precisionmachined track

- demand smooth accurate

Submit Your Enquiry