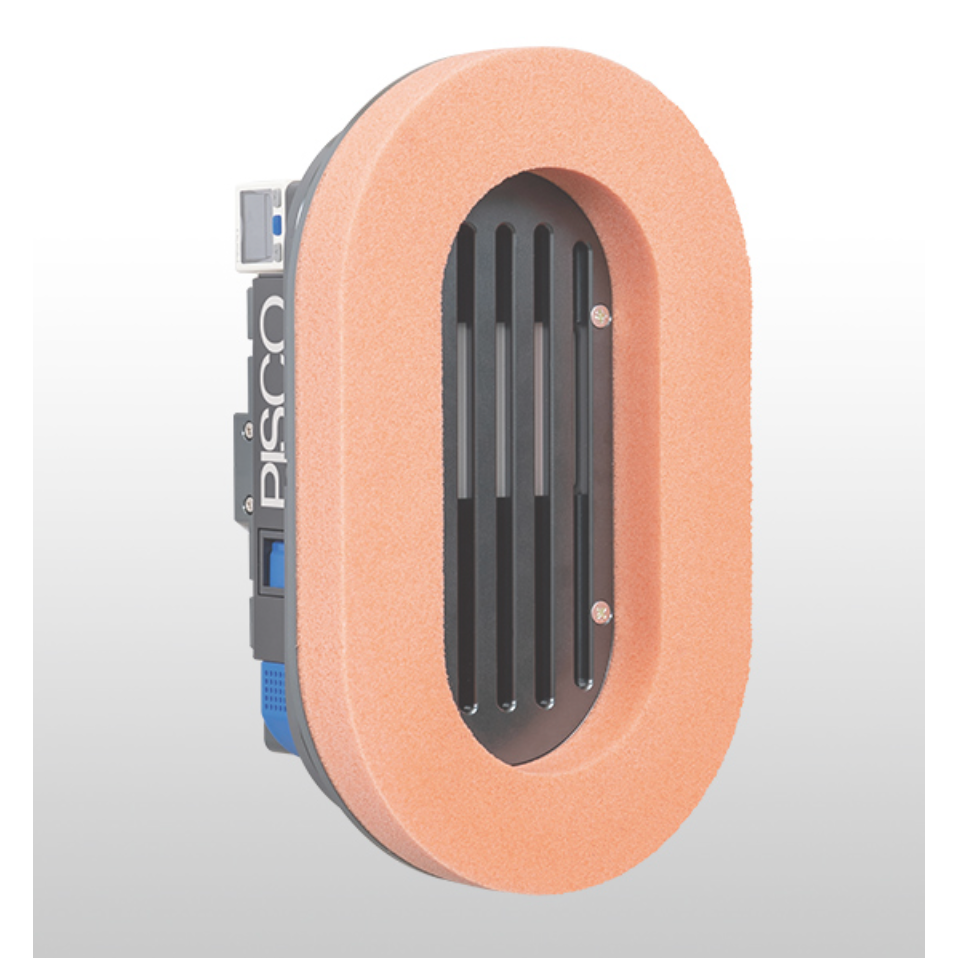

Pick and Place Automation with a Vacuum Gripper Suitable for Conveying Large Workpieces In today’s fast-paced manufacturing and packaging industries, pick and place automation has become essential for improving speed, consistency, and safety. One of the most effective technologies driving this automation is the vacuum gripper—especially when it comes to handling large and flat workpieces such as corrugated boxes, carton boxes, plastic parts, and automotive components. Why Use Vacuum Grippers in Pick and Place Systems? Vacuum grippers are a non-invasive, reliable method of gripping and moving items without requiring mechanical jaws or hooks. These grippers create suction through vacuum generators and can safely pick up items from above without causing damage or deformation. For large, lightweight, or delicate items, vacuum grippers offer superior control and minimal product damage. Applications in Industry Vacuum grippers are now widely used in automated material handling systems across various industries. Below are key sectors where vacuum-based pick and place systems are making a major impact: 1. Corrugated and Carton Box Handling Vacuum grippers are ideal for lifting corrugated boxes and carton packaging. Their large suction area ensures stability and control while moving lightweight packaging material, even when it's empty or partially filled. This is particularly useful in packaging lines and logistics where boxes need to be picked, placed, or stacked at high speed. 2. Plastic Parts Conveyance In industries such as injection molding, consumer electronics, or white goods, plastic parts vary in size, thickness, and rigidity. Vacuum grippers, especially those with soft or flexible suction cups, are perfect for picking irregular-shaped plastic parts without damaging the surface or structure. 3. Automotive Component Handling For automotive manufacturing, handling components like door panels, bumpers, and dashboards can be a challenge due to their size and shape. Vacuum grippers can be customized with multiple suction points and adjustable arms to handle such heavy and large parts with high precision. 4. E-Commerce and Logistics In warehouses and fulfillment centers, where large quantities of mixed product packaging need to be sorted and conveyed, vacuum pick and place systems significantly improve efficiency. Automated vacuum grippers can pick items directly from conveyor belts and place them into cartons or onto pallets with speed and accuracy. Key Advantages of Vacuum Grippers for Large Workpieces Gentle Handling: No scratches, dents, or deformation to the material. High-Speed Automation: Ideal for rapid pick and place in production or packaging lines. Versatility: Can handle a variety of surface materials—cardboard, plastic, metal, or painted surfaces. Energy Efficient: Modern vacuum generators offer energy-saving features for continuous operation. Custom Configurations: Can be tailored with multiple suction cups or adjustable mounts for unique applications. Choosing the Right Vacuum Gripper System When selecting a vacuum gripper for large workpieces, consider: Surface type (smooth, rough, porous) Workpiece size and weight Cycle time requirement Orientation and positioning accuracy Vacuum source compatibility Leading manufacturers such as Pisco Pneumatics, distributed in India by IBK Engineers Pvt Ltd, offer a wide range of vacuum grippers, suction cups, and vacuum generators specifically designed for robotic arms and pick-and-place automation. Their products are known for precision, modular design, and durability, suitable for both lightweight packaging and heavy industrial use. Conclusion As industries strive for greater automation, vacuum grippers for large workpiece handling offer a powerful solution. Whether it's corrugated box stacking, plastic part handling, or automotive component transfer, these grippers ensure reliable and efficient operation. For Indian manufacturers and integrators looking to enhance their pick-and-place systems, trusted brands like Pisco, supported by authorized distributors like IBK Engineers, deliver robust solutions ready for modern industry challenges.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Pick and Place Automation with a Vacuum Gripper...

2025-06-23T12:50:56

Pick and Place Automation with a Vacuum Gripper Suitable for Conveying Large Workpieces In today’s fast-paced manufacturing and packaging industries, pick and place automation has become essential for improving speed, consistency, and safety. One of the most effective technologies driving this automation is the vacuum gripper—especially when it comes to handling large and flat workpieces such as corrugated boxes, carton boxes, plastic parts, and automotive components. Why Use Vacuum Grippers in Pick and Place Systems? Vacuum grippers are a non-invasive, reliable method of gripping and moving items without requiring mechanical jaws or hooks. These grippers create suction through vacuum generators and can safely pick up items from above without causing damage or deformation. For large, lightweight, or delicate items, vacuum grippers offer superior control and minimal product damage. Applications in Industry Vacuum grippers are now widely used in automated material handling systems across various industries. Below are key sectors where vacuum-based pick and place systems are making a major impact: 1. Corrugated and Carton Box Handling Vacuum grippers are ideal for lifting corrugated boxes and carton packaging. Their large suction area ensures stability and control while moving lightweight packaging material, even when it's empty or partially filled. This is particularly useful in packaging lines and logistics where boxes need to be picked, placed, or stacked at high speed. 2. Plastic Parts Conveyance In industries such as injection molding, consumer electronics, or white goods, plastic parts vary in size, thickness, and rigidity. Vacuum grippers, especially those with soft or flexible suction cups, are perfect for picking irregular-shaped plastic parts without damaging the surface or structure. 3. Automotive Component Handling For automotive manufacturing, handling components like door panels, bumpers, and dashboards can be a challenge due to their size and shape. Vacuum grippers can be customized with multiple suction points and adjustable arms to handle such heavy and large parts with high precision. 4. E-Commerce and Logistics In warehouses and fulfillment centers, where large quantities of mixed product packaging need to be sorted and conveyed, vacuum pick and place systems significantly improve efficiency. Automated vacuum grippers can pick items directly from conveyor belts and place them into cartons or onto pallets with speed and accuracy. Key Advantages of Vacuum Grippers for Large Workpieces Gentle Handling: No scratches, dents, or deformation to the material. High-Speed Automation: Ideal for rapid pick and place in production or packaging lines. Versatility: Can handle a variety of surface materials—cardboard, plastic, metal, or painted surfaces. Energy Efficient: Modern vacuum generators offer energy-saving features for continuous operation. Custom Configurations: Can be tailored with multiple suction cups or adjustable mounts for unique applications. Choosing the Right Vacuum Gripper System When selecting a vacuum gripper for large workpieces, consider: Surface type (smooth, rough, porous) Workpiece size and weight Cycle time requirement Orientation and positioning accuracy Vacuum source compatibility Leading manufacturers such as Pisco Pneumatics, distributed in India by IBK Engineers Pvt Ltd, offer a wide range of vacuum grippers, suction cups, and vacuum generators specifically designed for robotic arms and pick-and-place automation. Their products are known for precision, modular design, and durability, suitable for both lightweight packaging and heavy industrial use. Conclusion As industries strive for greater automation, vacuum grippers for large workpiece handling offer a powerful solution. Whether it's corrugated box stacking, plastic part handling, or automotive component transfer, these grippers ensure reliable and efficient operation. For Indian manufacturers and integrators looking to enhance their pick-and-place systems, trusted brands like Pisco, supported by authorized distributors like IBK Engineers, deliver robust solutions ready for modern industry challenges.

2025-06-23T12:50:56

Keywords

- place automation

- heavy industrial

- size thickness

- place systems

- industries strive

- pickandplace automation

- authorized distributors

- indian manufacturers

- efficient operation

- powerful solution

- robotic arms

- wide range

- adjustable mounts

- scratches dents

- conveyor belts

- fulfillment centers

- adjustable arms

- challenge due

- partially filled

- causing damage

- moving items

- rapid pick

- vacuumbased pick

- safely pick

- large quantities

- large parts

- large lightweight

- handling large

- flat workpieces

- pisco supported

- lightweight packaging

- durability suitable

- large workpieces

- carton packaging

- key sectors

- automotive components

- vacuum generators

- vacuum gripperespecially

- packaging lines

- vacuum gripper

- vacuum grippers

- packaging industries pick

- pick items directly

- conveying large workpieces

- conveyed vacuum pick

- vacuum gripper suitable

- packaging lines versatility

- lifting corrugated boxes

- improving speed consistency

- vacuum gripper system

- shape vacuum grippers

- rigidity vacuum grippers

- industry vacuum grippers

- automotive component transfer

- pisco pneumatics distributed

- accuracy key advantages

- mixed product packaging

- grippers ensure reliable

- grippers create suction

- modern industry challenges

- precision modular design

- ibk engineers pvt

- unique applications choosing

- multiple suction cups

- multiple suction points

- door panels bumpers

- flexible suction cups

- requiring mechanical jaws

- noninvasive reliable method

- effective technologies driving

- todays fastpaced manufacturing

Submit Your Enquiry