Description

Product details

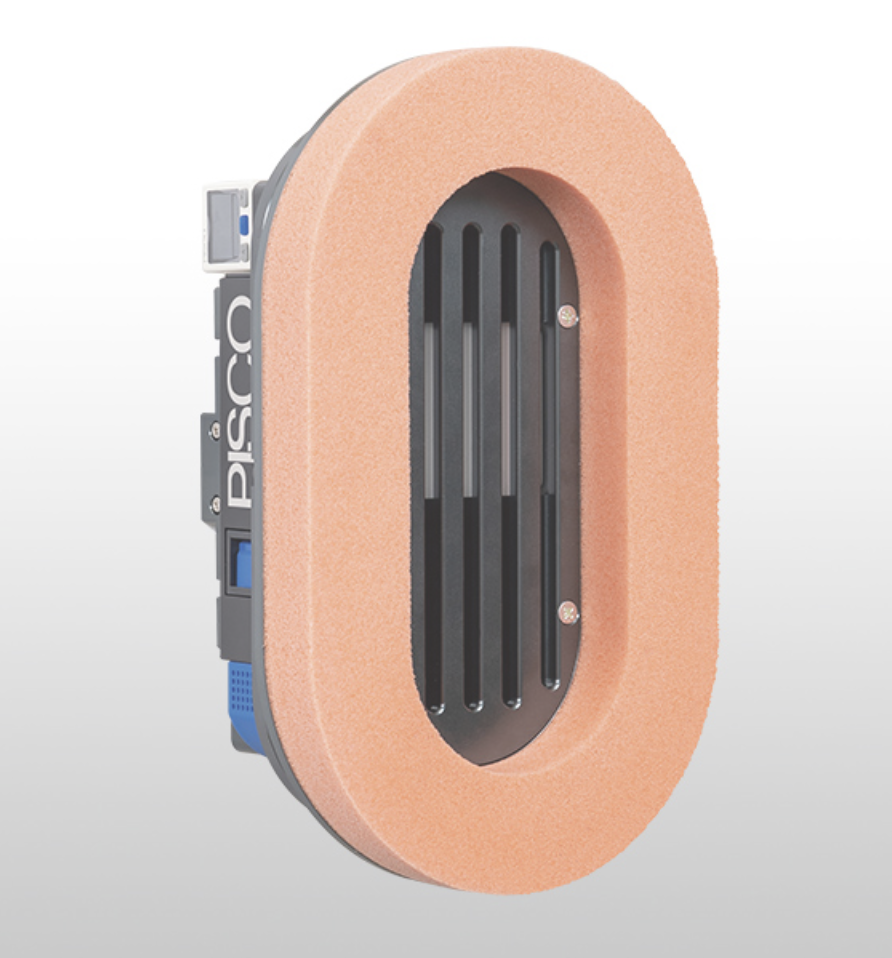

Understanding Pneumatic Vacuum Cups: Essential Guide for Industrial Users Pneumatic vacuum cups—also known as suction cups or vacuum pads—are critical components in many industrial automation systems. These devices provide a fast, reliable, and non-damaging method of handling a variety of materials using the power of vacuum. Whether it’s in robotic pick-and-place applications, packaging lines, CNC machines, or sheet metal handling, vacuum cups improve productivity and reduce mechanical complexity. In this article, we will explore the working principle, types, applications, selection guidelines, maintenance tips, and advantages of pneumatic vacuum cups, helping end users make informed decisions when integrating them into their machinery or processes. 1. What is a Pneumatic Vacuum Cup? A pneumatic vacuum cup is a soft, flexible device made from rubber, silicone, or polyurethane that attaches to the surface of an object by creating a vacuum (negative pressure). It is connected to a vacuum generator—such as a venturi ejector or vacuum pump—through a pneumatic line. When the vacuum is applied, atmospheric pressure pushes the cup against the object, creating a secure grip. Once the vacuum is released (by introducing positive air pressure or cutting off the vacuum), the cup detaches from the object. This contactless, damage-free gripping system is ideal for delicate or irregularly shaped items. 2. How Does a Vacuum Cup Work? The operation of a vacuum cup relies on a few simple principles: Vacuum Generation: A vacuum generator removes air from the space inside the cup, reducing the pressure. Atmospheric Pressure: The external air pressure (about 1 bar) presses the cup onto the object. Sealing Lip: The flexible edge of the vacuum cup forms a seal on the surface of the object to prevent air leakage. Holding Force: The holding force is proportional to the vacuum level and the surface area of the cup in contact with the object. This simple yet effective mechanism enables the lifting, holding, and movement of a wide variety of objects with minimal damage or marking. 3. Types of Pneumatic Vacuum Cups Depending on application and material, vacuum cups come in several types: Flat Vacuum Cups: Ideal for flat, smooth surfaces like glass, sheet metal, or plastic panels. Offers quick response time and high stability. Bellows Vacuum Cups: Equipped with one or more folds (bellows), allowing them to adapt to uneven surfaces or curved profiles. Suitable for lightweight items. Oval Vacuum Cups: Designed for narrow or elongated parts, such as metal profiles or packaging cartons. Deep Vacuum Cups: Provide deep reach for handling objects with varying height or recessed surfaces. Foam Vacuum Pads: Used for extremely uneven or porous materials like wood or fabric. Materials used include: Silicone: High heat resistance, food-grade applications Nitrile Rubber (NBR): General-purpose, oil-resistant Polyurethane (PU): Durable, high wear resistance EPDM: Resistant to ozone and outdoor environments 4. Applications of Vacuum Cups Vacuum cups are used in nearly every industry, including: Automotive: Handling metal sheets for stamping, welding, and painting Packaging: Pick-and-place of cartons, bags, and boxes Electronics: Handling delicate parts like LCD panels or PCB boards Glass Industry: Lifting glass sheets for cutting, cleaning, or transport Woodworking: Vacuum clamping and part transfer in CNC routers Food Processing: Contactless handling of bakery goods, fruits, and packaged products Plastic Molding: Removing parts from injection molds They are widely used in robotic arms, vacuum lifters, conveyor lines, CNC machines, and automated storage systems. 5. How to Select the Right Vacuum Cup Choosing the correct vacuum cup for your application is key to optimal performance. Consider the following factors: Surface Texture: Smooth surfaces work well with flat cups, while textured or uneven surfaces require bellows or foam pads. Material Compatibility: Ensure the cup material is suitable for the workpiece (e.g., silicone for food, NBR for oily metal). Weight of Object: Calculate the holding force required, considering acceleration and safety factors. Vacuum Source: Ensure compatibility with the vacuum generator (pump or ejector) and tubing. Cycle Time: Some cups are optimized for fast release and grip cycles. Environment: High temperature, exposure to chemicals, or outdoor use may require special materials. A general rule: Use multiple cups for large or heavy objects to distribute the load and enhance safety. 6. Maintenance and Troubleshooting To keep vacuum cups working efficiently, follow these best practices: Regular Inspection: Check for cracks, hardening, or wear on the lip area. Replace worn cups to maintain sealing performance. Cleanliness: Keep the cups and surrounding surfaces clean. Dust or oil can degrade the seal. Leak Testing: Check vacuum lines and fittings for leaks that can reduce holding force. Filter.