Description

Product details

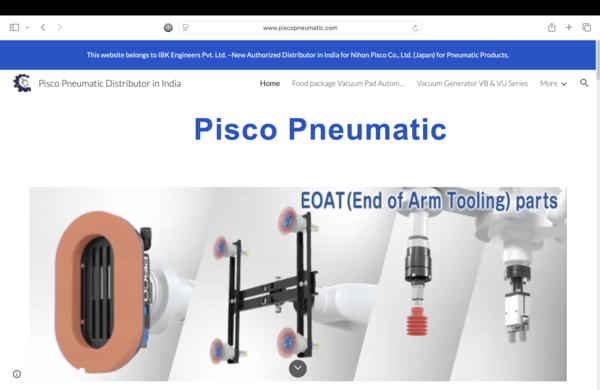

End of Arm Tooling (EOAT) for Robotic Arms End of Arm Tooling (EOAT) refers to the devices mounted at the wrist of a robotic arm that enable the robot to interact with a workpiece. EOAT is a critical element in robotic automation, as overall system performance, accuracy, and reliability depend heavily on correct EOAT design and selection. For design engineers, EOAT must be selected based on payload, part geometry, cycle time, and process requirements. Common EOAT types include mechanical grippers, vacuum suction cups, magnetic grippers, welding guns, dispensing nozzles, and tool changers. Lightweight yet rigid construction is essential to minimize inertia and improve robot speed and positioning accuracy. Materials such as aluminum alloys, stainless steel, and engineering plastics are widely used to balance strength and weight. Modular EOAT designs are preferred, as they allow quick changes and future process flexibility. In applications like pick-and-place, assembly, packaging, and machine tending, vacuum EOAT offers gentle handling of delicate parts, while mechanical grippers provide higher gripping force and repeatability. Tool changers allow a single robot to perform multiple operations, increasing overall equipment effectiveness (OEE). From a maintenance perspective, EOAT should be designed for easy access and quick replacement of wear parts such as seals, suction cups, fingers, and sensors. Standardized fittings, push-in pneumatic connections, and quick-release mechanisms reduce downtime during servicing. Regular inspection of hoses, vacuum lines, fasteners, and sensors ensures consistent performance and prevents unexpected failures. Proper EOAT selection and maintenance directly impact robot uptime, product quality, and safety. By integrating robust EOAT design with preventive maintenance practices, manufacturers can maximize the efficiency, flexibility, and long-term reliability of robotic automation systems.