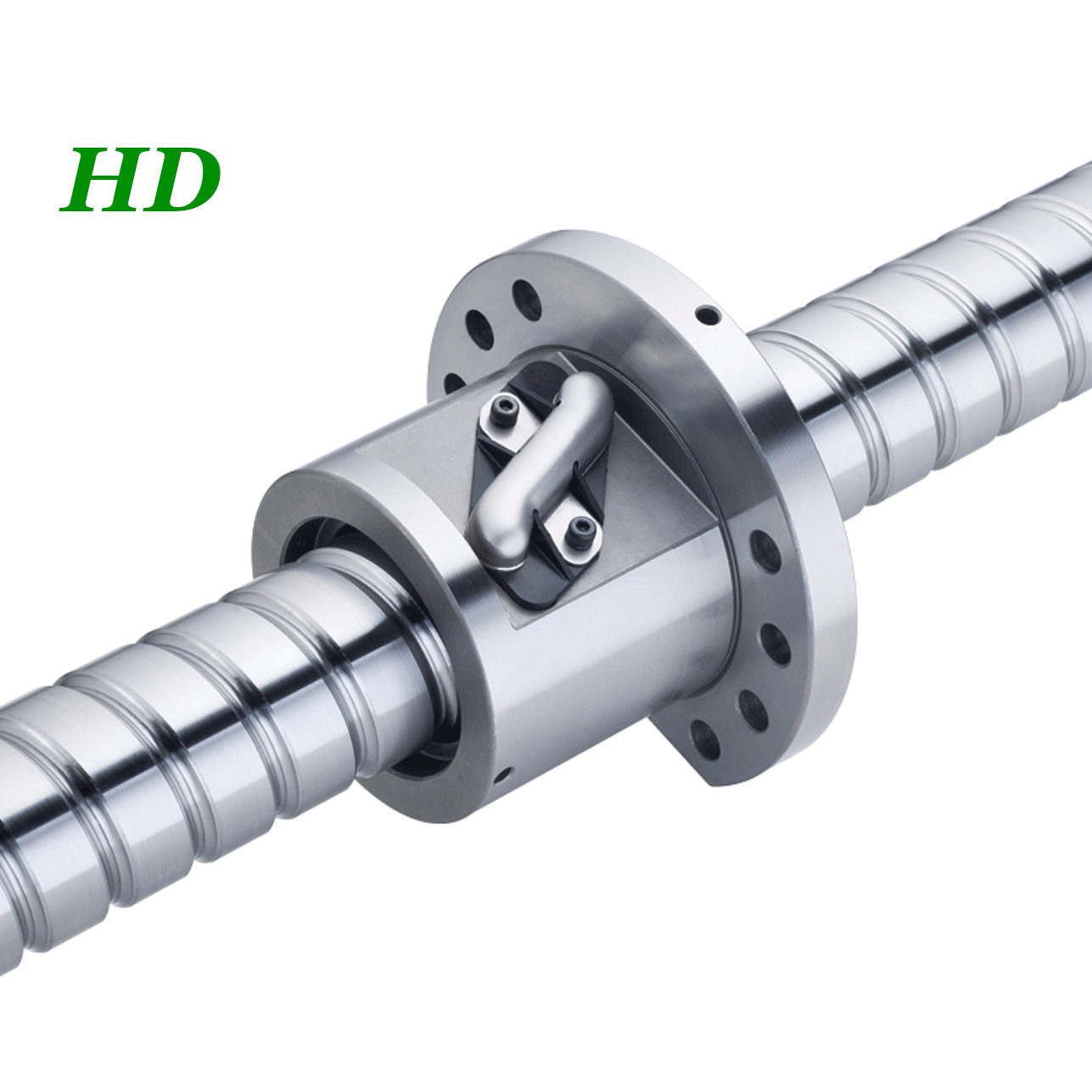

Understanding Ball Screw Bending: Causes, Solutions, and Tolerance Guidelines Causes of Ball Screw Bending Manufacturing Defects: Imperfections during production such as uneven material distribution or improper machining can introduce bends. Improper Handling: Mishandling during transportation or installation can result in physical deformations. Overloading: Subjecting the ball screw to loads beyond its capacity can cause bending. Thermal Expansion: Uneven heating or cooling can lead to warping or bending due to differential expansion. Improper Mounting: Incorrect alignment during installation can exert lateral forces, leading to bending over time. Eliminating Bends in Ball Screws Quality Control: Implement rigorous inspection processes during and after manufacturing to detect and correct any deviations. Proper Handling Procedures: Use appropriate lifting and transport equipment to prevent accidental damage. Load Management: Ensure the ball screw is used within its specified load limits. Thermal Management: Employ cooling systems or insulation to minimize thermal effects. Accurate Installation: Align the ball screw precisely during installation, using alignment tools to prevent undue stress. Tolerance Guidelines The allowable tolerance for ball screw bending varies based on the diameter and application requirements. General industry standards suggest: Small-Diameter Screws (Up to 16 mm): Typically, a maximum bend tolerance of 0.015 mm per 300 mm length is acceptable. Medium-Diameter Screws (16 mm to 50 mm): Tolerance may range from 0.015 mm to 0.05 mm per 300 mm. Large-Diameter Screws (Above 50 mm): Larger screws may have a tolerance range of 0.05 to 0.1 mm per 300 mm, depending on the application’s precision needs. Conclusion Ball screw bending can significantly impact machine performance and precision. Understanding its causes, implementing preventive measures, and adhering to appropriate tolerance limits are crucial for maintaining the integrity and efficiency of ball screws in various industrial applications.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Understanding Ball Screw Bending: Causes, Solut...

2025-01-08T03:52:15

Understanding Ball Screw Bending: Causes, Solutions, and Tolerance Guidelines Causes of Ball Screw Bending Manufacturing Defects: Imperfections during production such as uneven material distribution or improper machining can introduce bends. Improper Handling: Mishandling during transportation or installation can result in physical deformations. Overloading: Subjecting the ball screw to loads beyond its capacity can cause bending. Thermal Expansion: Uneven heating or cooling can lead to warping or bending due to differential expansion. Improper Mounting: Incorrect alignment during installation can exert lateral forces, leading to bending over time. Eliminating Bends in Ball Screws Quality Control: Implement rigorous inspection processes during and after manufacturing to detect and correct any deviations. Proper Handling Procedures: Use appropriate lifting and transport equipment to prevent accidental damage. Load Management: Ensure the ball screw is used within its specified load limits. Thermal Management: Employ cooling systems or insulation to minimize thermal effects. Accurate Installation: Align the ball screw precisely during installation, using alignment tools to prevent undue stress. Tolerance Guidelines The allowable tolerance for ball screw bending varies based on the diameter and application requirements. General industry standards suggest: Small-Diameter Screws (Up to 16 mm): Typically, a maximum bend tolerance of 0.015 mm per 300 mm length is acceptable. Medium-Diameter Screws (16 mm to 50 mm): Tolerance may range from 0.015 mm to 0.05 mm per 300 mm. Large-Diameter Screws (Above 50 mm): Larger screws may have a tolerance range of 0.05 to 0.1 mm per 300 mm, depending on the application’s precision needs. Conclusion Ball screw bending can significantly impact machine performance and precision. Understanding its causes, implementing preventive measures, and adhering to appropriate tolerance limits are crucial for maintaining the integrity and efficiency of ball screws in various industrial applications.

2025-01-08T03:52:15

Keywords

- 01 mm

- 005 mm

- 0015 mm

- 300 mm depending

- 300 mm length

- 16 mm typically

- bending due

- tolerance range

- 50 mm tolerance

- industrial applications

- precision understanding

- applications precision

- alignment tools

- transport equipment

- improper machining

- tolerance limits

- allowable tolerance

- tolerance guidelines

- ball screws

- ball screw

- ball screw precisely

- maximum bend tolerance

- implementing preventive measures

- time eliminating bends

- uneven material distribution

Submit Your Enquiry