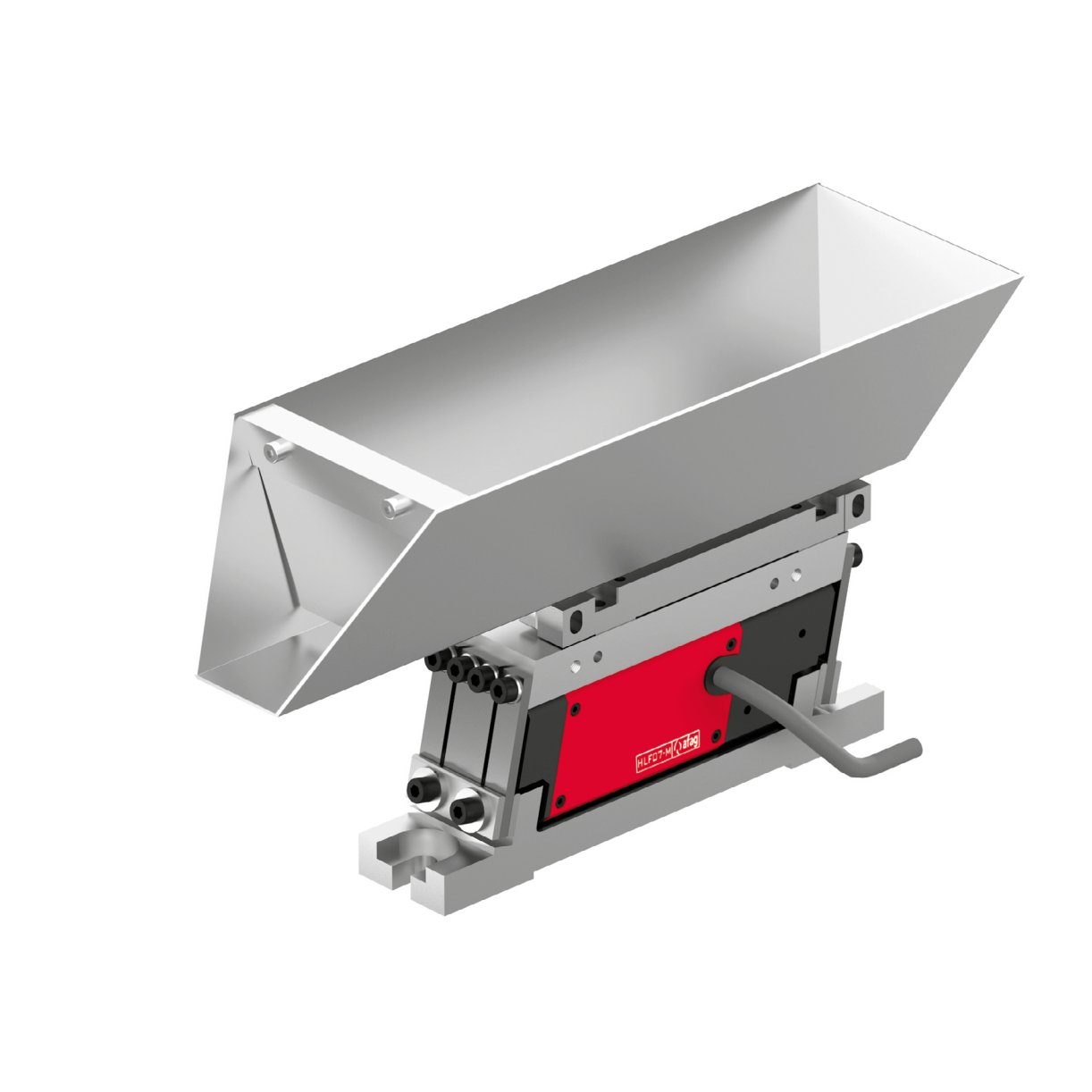

Afag linear feeders Afag linear feeders are essential components in automated assembly lines, designed to transport oriented parts from vibratory bowl feeders to the next processing stage. They are known for their precision, reliability, and smooth operation, making them suitable for various industrial applications. Key Features of Afag Linear Feeders Precision Engineering: Ensures accurate and consistent part handling and orientation. Durability: Built from high-quality materials to withstand demanding industrial environments. Customization: Tailored to meet specific application requirements, including the size, shape, and material of the fed parts. Smooth Operation: Designed for quiet and efficient movement of parts with minimal wear and tear. Versatility: Suitable for use in diverse industries, such as automotive, electronics, pharmaceuticals, and consumer goods. Components and Working Principles Linear Track: A straight or curved track where parts are transported. The track can be customized based on part size and shape. Drive Unit: Generates controlled vibrations that move the parts along the linear track. Afag’s drive technology ensures smooth and consistent movement. Controller: Allows for precise adjustment of vibration settings to optimize the feeding process for different parts. Sensors: Optional sensors can be integrated to monitor and control the flow of parts, ensuring a steady and consistent feed rate. Applications Afag linear feeders are used in a variety of applications, including: Automotive Industry: Transporting components such as springs, screws, and clips from bowl feeders to assembly stations. Electronics Manufacturing: Moving small electronic parts and connectors between stages of the assembly process. Pharmaceutical Industry: Handling medical device components with high precision. Consumer Goods: Feeding parts for the assembly of various consumer products. Online Marketplaces: Explore online industrial supply platforms like ThomasNet, DirectIndustry, or specialized automation supply www.ibizkart.com, which lists Afag products. Following these steps, you can efficiently locate an Afag linear feeder dealer or distributor near you to meet your automation needs. If you provide your specific location, I can assist further in identifying nearby dealers.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Afag linear feeders Afag linear feeders are es...

2024-06-02T05:24:16

Afag linear feeders Afag linear feeders are essential components in automated assembly lines, designed to transport oriented parts from vibratory bowl feeders to the next processing stage. They are known for their precision, reliability, and smooth operation, making them suitable for various industrial applications. Key Features of Afag Linear Feeders Precision Engineering: Ensures accurate and consistent part handling and orientation. Durability: Built from high-quality materials to withstand demanding industrial environments. Customization: Tailored to meet specific application requirements, including the size, shape, and material of the fed parts. Smooth Operation: Designed for quiet and efficient movement of parts with minimal wear and tear. Versatility: Suitable for use in diverse industries, such as automotive, electronics, pharmaceuticals, and consumer goods. Components and Working Principles Linear Track: A straight or curved track where parts are transported. The track can be customized based on part size and shape. Drive Unit: Generates controlled vibrations that move the parts along the linear track. Afag’s drive technology ensures smooth and consistent movement. Controller: Allows for precise adjustment of vibration settings to optimize the feeding process for different parts. Sensors: Optional sensors can be integrated to monitor and control the flow of parts, ensuring a steady and consistent feed rate. Applications Afag linear feeders are used in a variety of applications, including: Automotive Industry: Transporting components such as springs, screws, and clips from bowl feeders to assembly stations. Electronics Manufacturing: Moving small electronic parts and connectors between stages of the assembly process. Pharmaceutical Industry: Handling medical device components with high precision. Consumer Goods: Feeding parts for the assembly of various consumer products. Online Marketplaces: Explore online industrial supply platforms like ThomasNet, DirectIndustry, or specialized automation supply www.ibizkart.com, which lists Afag products. Following these steps, you can efficiently locate an Afag linear feeder dealer or distributor near you to meet your automation needs. If you provide your specific location, I can assist further in identifying nearby dealers.

2024-06-02T05:24:16

Keywords

- use

- flow

- tear

- steps

- shape

- clips

- quiet

- steady

- screws

- stages

- springs

- variety

- accurate

- straight

- ibizkart

- ThomasNet

- part size

- connectors

- Drive Unit

- Durability

- Controller

- Versatility

- orientation

- reliability

- distributor

- minimal wear

- Key Features

- Linear Track

- curved track

- Customization

- Afag products

- DirectIndustry

- oriented parts

- nearby dealers

- high precision

- consumer goods

- different parts

- pharmaceuticals

- feeding process

- automation needs

- Optional sensors

- drive technology

- smooth operation

- assembly process

- assembly stations

- specific location

- efficient movement

- precise adjustment

- vibration settings

- diverse industries

- Working Principles

- Automotive Industry

- consistent movement

- Online Marketplaces

- Afag linear feeders

- essential components

- consistent feed rate

- next processing stage

- Precision Engineering

- controlled vibrations

- small electronic parts

- vibratory bowl feeders

- high-quality materials

- Pharmaceutical Industry

- automated assembly lines

- consistent part handling

- medical device components

- various consumer products

- Afag linear feeder dealer

- Electronics Manufacturing

- specialized automation supply

- various industrial applications

- specific application requirements

- demanding industrial environments

- online industrial supply platforms

Submit Your Enquiry