Description

Product details

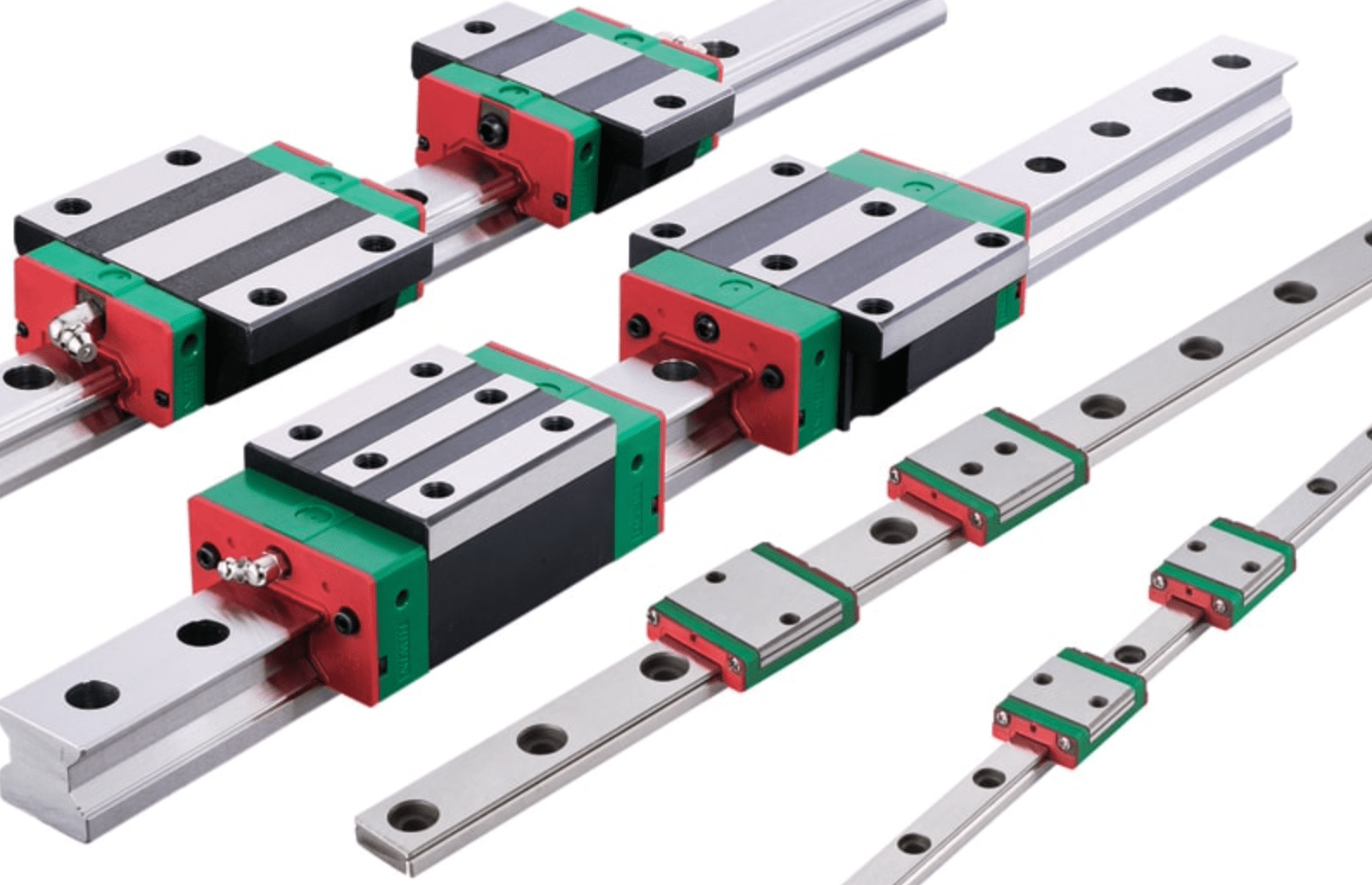

Understanding LM Guides (Linear Guides): A Comprehensive Overview LM Guides, also known as Linear Guides, play a pivotal role in various industries where precise linear motion is crucial. These guides facilitate smooth movement in machines and mechanisms, ensuring accuracy and reliability. Understanding LM Guides and their diverse applications is fundamental in the realm of engineering and machinery. What Are LM Guides? LM Guides, or Linear Guides, are mechanical systems designed to facilitate linear motion with high precision and rigidity. They consist of rails and sliders/bearings that enable smooth and accurate movement along a linear axis. These components are engineered to minimize friction and ensure optimal performance in machinery and mechanical systems. Types of LM Guides: LM Guides come in various types, each tailored for specific applications: Ball Guides: Utilize recirculating balls to reduce friction and provide smooth linear motion. Roller Guides: Employ rollers for heavier loads and increased rigidity. Slide Guides: Ideal for compact designs, using sliding contact to achieve linear motion. Crossed Roller Guides: Offer high rigidity and accuracy by using crossed cylindrical rollers. Applications: The versatility of LM Guides makes them integral across multiple industries: Manufacturing: Used in CNC machines, robotics, and automated manufacturing processes for precision motion control. Medical Equipment: Found in medical devices, imaging systems, and surgical robots requiring accurate linear movement. Aerospace and Automotive: Utilized in aircraft components, vehicle assembly, and navigation systems for reliable motion. Choosing the Right LM Guide: Selecting the appropriate LM Guide depends on factors like load capacity, precision, speed, environment, and required maintenance. Engineers assess these factors to determine the most suitable type and size of LM Guide for a particular application. Maintenance and Care: Regular maintenance is crucial to ensure the longevity and performance of LM Guides. Proper lubrication and periodic inspection for wear and tear are essential practices. Conclusion: In the realm of machinery and engineering, LM Guides (Linear Guides) stand as indispensable components, enabling precise and reliable linear motion. Understanding their types, applications, and maintenance is key in leveraging their potential across diverse industries.