Description

Product details

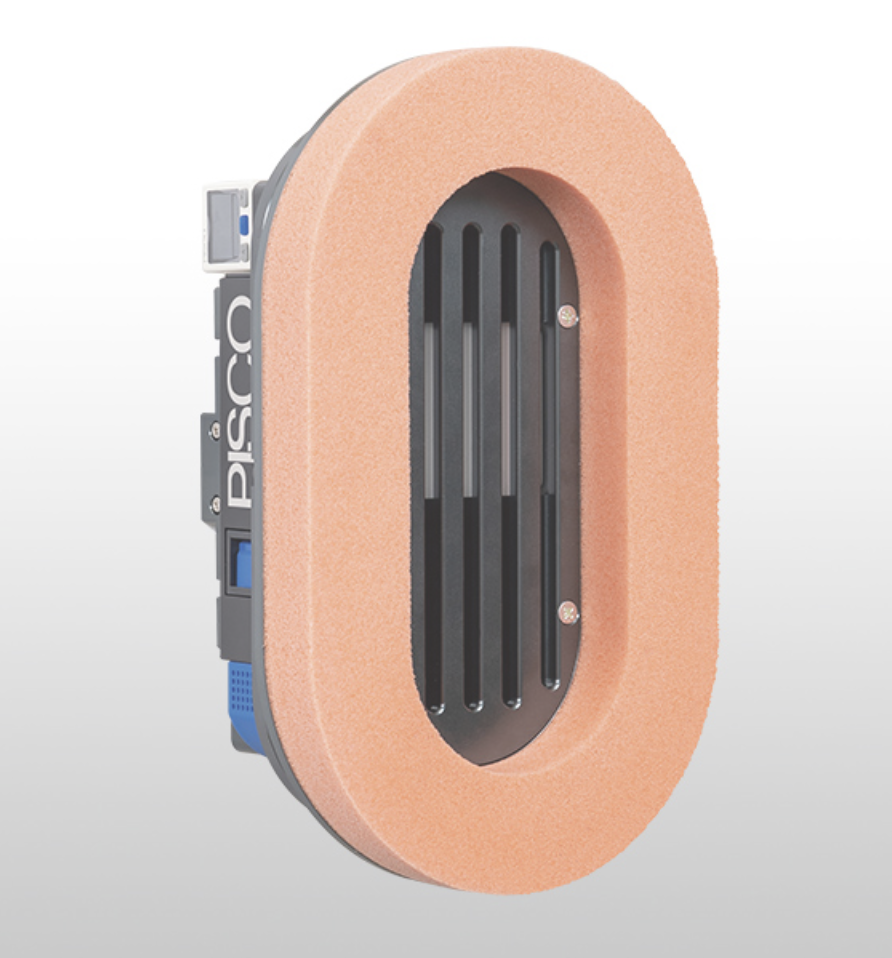

Vacuum Ejector Built-in Suction Pad Air Tweezers The Perfect Solution for Precision Handling In modern production and assembly lines, handling small and delicate parts such as diamonds, jewellery components, electronic IC chips, watches, phones, toys, and miniature screws requires advanced tools that combine efficiency with care. One such innovative tool is the Vacuum Ejector Built-in Suction Pad Air Tweezer, designed for industries where precision, cleanliness, and speed are critical. What is a Vacuum Ejector Built-in Suction Pad Air Tweezer? These air tweezers integrate a mini vacuum ejector with a suction pad, allowing operators or robotic systems to pick and place tiny components without causing scratches, marks, or static damage. Unlike traditional tweezers, which rely on manual pressure, air tweezers use compressed air and the Venturi effect to generate vacuum instantly. This ensures smooth lifting, stable gripping, and gentle release of sensitive parts. Key Applications The vacuum ejector suction pad tweezers are widely used across multiple industries: Diamond & Jewelry Industry – Safe handling of precious stones and delicate metal pieces without leaving fingerprints or marks. Electronics Manufacturing – Efficient pick-and-place of IC chips, circuit boards, and semiconductors without static discharge. Watch & Phone Assembly – Handling of precision parts like gears, glass screens, and connectors. Toy & Consumer Goods Production – Quick and safe placement of tiny screws, clips, and molded parts. Medical & Laboratory Equipment – Gentle handling of micro-components for medical device assembly. Benefits of Using Vacuum Air Tweezers Precision & Reliability – Stable suction ensures parts do not slip during handling. Non-Marking & Anti-Static – Essential for diamonds, polished metals, and electronic components. Compact & Lightweight – Easy to use for both manual operators and automated robots. Cost-Effective Production – Reduces damage, improves yield, and increases productivity. Versatility – Compatible with various suction pad sizes and materials (silicone, urethane, non-marking). Why Manufacturers Prefer Vacuum Suction Pad Tweezers In Bangalore, Chennai, Hyderabad, Pune, Mumbai, Ahmedabad, and Delhi, precision industries are increasingly shifting to vacuum ejector air tweezers for small component handling. With imported Japanese technology from brands like Pisco, these tools ensure long life, stable operation, and low air consumption, making them ideal for mass production setups. Conclusion Whether you are in electronics assembly, jewellery making, diamond processing, watch repair, or phone manufacturing, the Vacuum Ejector Built-in Suction Pad Air Tweezer is the wise choice for precision, safety, and efficiency. By adopting this advanced handling tool, industries can reduce errors, enhance product quality, and expedite production.