Description

Product details

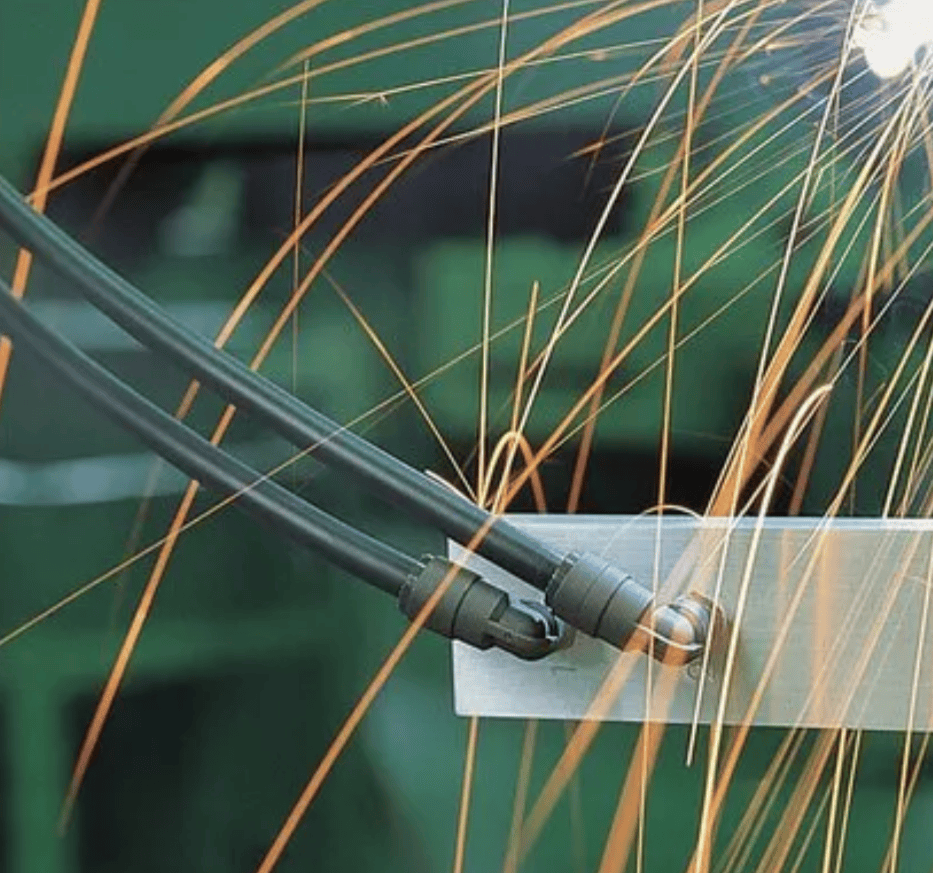

Vacuum Suction Pads for Robots: Material Properties, Designs, and System Integration for Engineers Vacuum suction pads are critical components in robotic automation systems. From robotic arms on automotive assembly lines to collaborative robots (cobots) in packaging and logistics, suction pads provide efficient, flexible, and reliable gripping solutions. For engineers, selecting the right vacuum suction pad for robots requires understanding material properties, pad geometry, and integration with the robotic vacuum system. The right choice can significantly improve precision, reduce cycle times, and extend system life. 1. Why Robots Use Vacuum Suction Pads Robotic vacuum gripping offers: Non-damaging handling – ideal for fragile items like glass or electronics. Versatility – suitable for objects with varying shapes and surfaces. High speed and accuracy – enabling fast pick-and-place automation. Reduced mechanical complexity – no need for mechanical grippers in many cases. By pairing the right pad material and design with the robotic task, engineers can maximize productivity and minimize downtime. 2. Suction Pad Materials and Applications 🔹 Nitrile Rubber (NBR) Strengths: Oil-resistant, reliable for standard applications. Temperature Range: -10°C to +70°C. Use Cases: General-purpose robotic handling in packaging, logistics, and machine tending. 🔹 Silicone Rubber (VMQ) Strengths: High heat resistance, FDA-compliant for food handling, flexible for uneven surfaces. Temperature Range: -30°C to +200°C. Use Cases: Food automation robots, pharmaceutical packaging, high-temperature applications. 🔹 Polyurethane (PU) Strengths: Durable, abrasion-resistant, excellent grip on rough or porous surfaces. Use Cases: Robotic systems handling wood, sheet metal, cartons, or abrasive parts. 🔹 Viton (FKM) Strengths: Outstanding resistance to chemicals, oils, and high heat. Temperature Range: -20°C to +200°C. Use Cases: Industrial robots in chemical plants, automotive painting, aerospace applications. 3. Suction Pad Designs for Robotic Applications Different robotic tasks require different suction pad geometries: 🔹 Flat Suction Pads Best for: Flat or slightly curved workpieces. Advantages: Fast cycle times, high stability, secure grip. Robotic Example: Pick-and-place robots for electronics or glass panels. 🔹 Bellows Suction Pads Best for: Uneven or delicate workpieces. Advantages: Height compensation, shock absorption, gentle gripping. Robotic Example: Cobots handling irregular plastics or fragile packaging. 🔹 Oval Suction Pads Best for: Long, narrow workpieces with limited gripping area. Advantages: Maximized contact, stable hold on strips or elongated parts. Robotic Example: Automotive robots handling bumpers, sheet metal, or extrusions. 4. System Integration: Beyond the Pad For reliable robotic vacuum gripping, engineers must design the complete vacuum system: Vacuum Generators: Pumps and ejectors that create negative pressure for suction. Vacuum Filters: Prevent contaminants from damaging generators and robotic actuators. Tubing and Fittings: Maintain airflow efficiency with minimal leakage. Control Valves & Sensors: Provide smart monitoring, feedback, and precise control of gripping force. Modern robotic systems often integrate vacuum sensors with PLC or cobot software, enabling intelligent grip detection and automated fault handling. 5. Engineering Takeaways Material Selection – Match pad material (NBR, VMQ, PU, FKM) to environment and workpiece. Design Choice – Use flat, bellows, or oval pads depending on geometry and fragility. System Integration – Ensure a complete setup with filters, generators, tubing, and sensors. Application Focus – Consider speed, durability, and surface type for optimal robotic performance. Vacuum suction pads for robots may look simple, but the right engineering choices make the difference between a smooth-running automation line and costly downtime. Product to target: vacuum suction pads for robots, robotic suction grippers, industrial robot vacuum pads, automation suction pads, robotic handling solutions, suction pad materials, bellows suction pads for robots, flat suction pads, oval suction pads, vacuum gripping systems.