Description

Product details

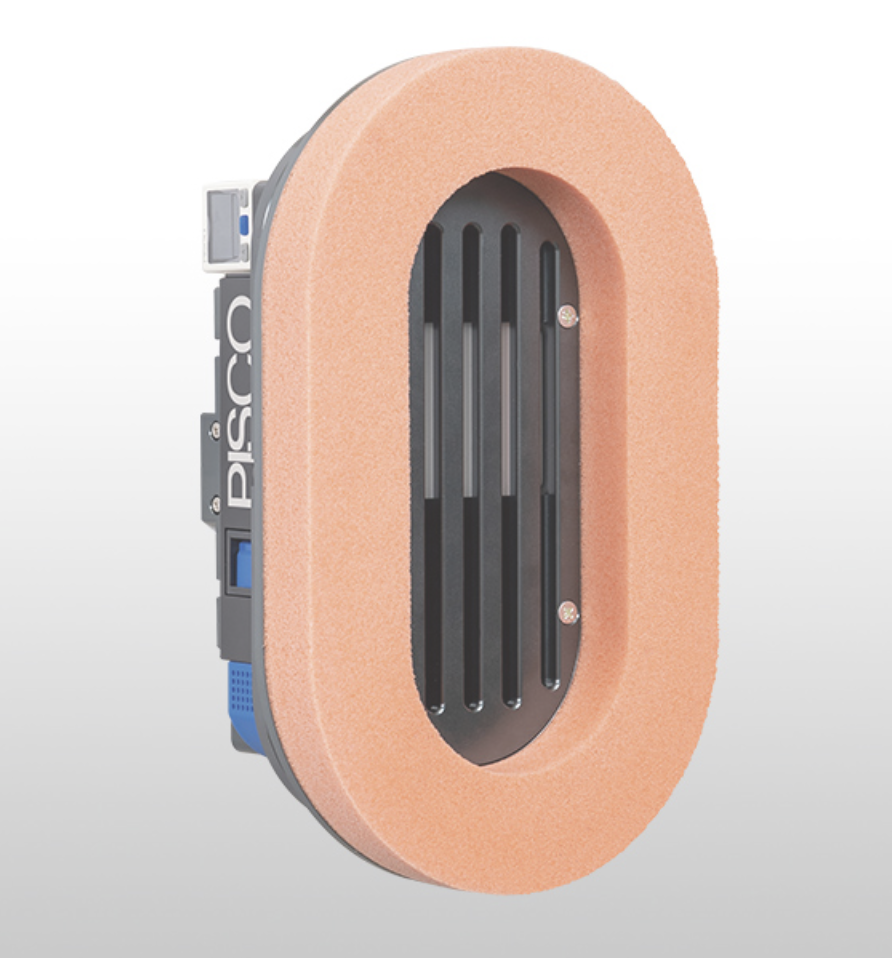

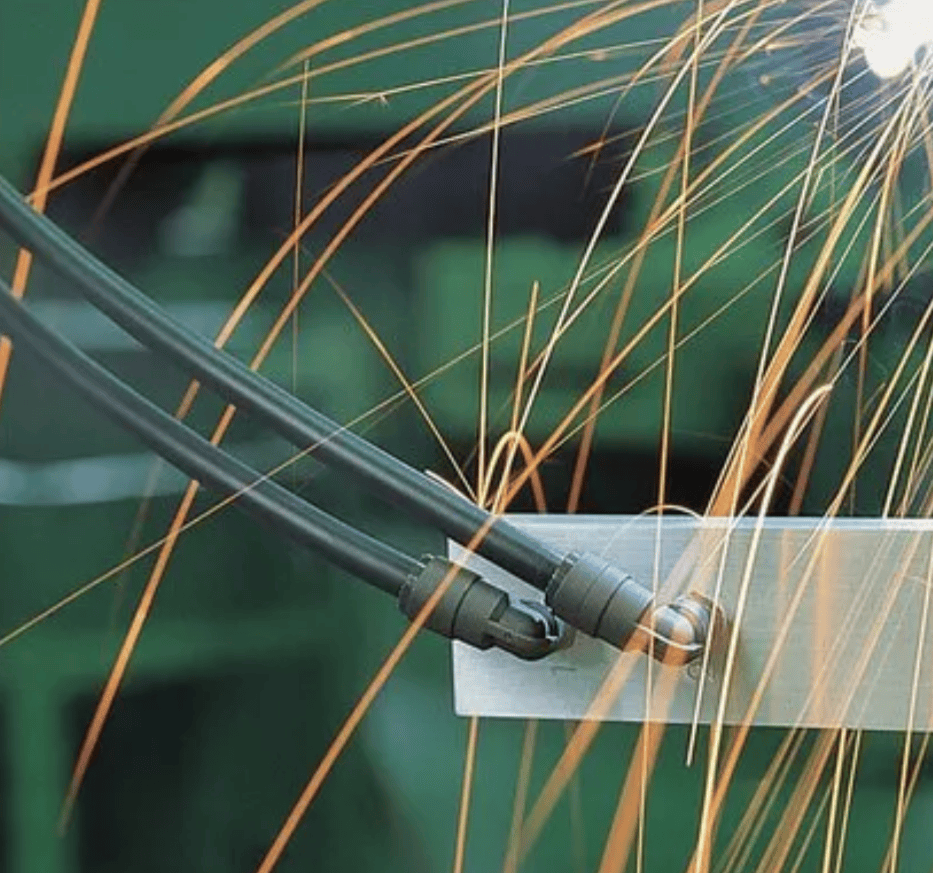

Vacuum Suction Cups India – Engineering Guide & Supplier Insights Introduction Vacuum suction cups are one of the most widely used gripping solutions in automation, robotics, and industrial handling systems. By using controlled vacuum pressure, these cups enable fast, reliable, and non-damaging handling of objects ranging from delicate glass panels to heavy automotive sheets. In India, industries such as automotive, electronics, packaging, logistics, food processing, glass, and solar panel manufacturing are increasingly adopting vacuum handling solutions. Selecting the right suction cup material and design is crucial for maximizing efficiency and minimizing downtime. As an established supplier, dealer, distributor, and exporter in India, IBK Engineers Pvt Ltd, Bangalore, provides engineers and procurement managers with proven vacuum suction cup solutions for a wide range of applications. What are Vacuum Suction Cups? A vacuum suction cup (or vacuum pad) works on the principle of pressure difference. When connected to a vacuum source (pump or ejector), the cup seals tightly against the object’s surface, creating a secure grip. This simple yet highly effective technology allows: Gentle handling of delicate or polished parts Fast cycle times in automated systems Reduced mechanical complexity compared to grippers Suction Cup Materials & Applications Choosing the right material is a critical engineering decision: Nitrile Rubber (NBR): Oil-resistant, general-purpose use. Temperature range -10°C to +70°C. Ideal for automotive assembly and handling oily metal sheets. Silicone Rubber (VMQ): High-temperature performance (-30°C to +200°C), food-grade and FDA-compliant. Suitable for food packaging, hot components, and medical equipment. Polyurethane (PU): High wear resistance, tear-proof, and durable. Best for high-speed pick-and-place in packaging, plastics, and films. EPDM Rubber: Excellent resistance to weather, ozone, and chemicals. Temperature range -30°C to +120°C. Common in glass handling, solar panel manufacturing, and outdoor applications. Types of Suction Cups Engineers can select from different designs based on application needs: Flat Cups: Best for smooth, flat surfaces with fast grip and release. Bellows (Accordion) Cups: Flexible design to handle curved or uneven surfaces and absorb height variations. Oval Cups: Narrow shape ideal for profiles, strips, or cylindrical objects. Mark-Free Cups: Special compounds for scratch-free handling of glass, painted, or sensitive surfaces. Key Selection Criteria for Engineers When designing vacuum handling systems, consider: Surface Characteristics: Smooth, rough, oily, or porous. Load & Grip Strength: Diameter and number of cups determine lifting capacity. Operating Environment: Temperature, humidity, exposure to chemicals, or UV. Cycle Speed & Durability: For high-speed automation, materials like PU offer extended life. System Compatibility: Leakage rates, vacuum generator capacity, and energy efficiency. Industries Using Vacuum Suction Cups in India Automotive: Body panels, windshields, and interior components Electronics: PCB transfer, LCD glass handling Packaging: Bottles, cartons, flexible films Logistics: Palletizing, warehouse automation, e-commerce packaging Food & Beverage: Hygienic suction cups for bakery, confectionery, and dairy Glass & Solar: Large, fragile panels without scratches Why Choose IBK Engineers Pvt Ltd? As a trusted supplier, distributor, dealer, and exporter of vacuum suction cups in India, IBK Engineers Pvt Ltd, Bangalore, brings: Technical expertise in pneumatic and vacuum technology Wide range of suction cup materials and designs Reliable sourcing for both domestic and export requirements Support for engineers in selecting the right solution for their applications Conclusion Vacuum suction cups are critical to modern automation and industrial handling systems. With the right material, design, and supplier support, industries can achieve higher productivity, reduced downtime, and safe handling of sensitive materials. For reliable sourcing in India, partner with IBK Engineers Pvt Ltd, Bangalore – your trusted supplier, distributor, and exporter of vacuum suction cups and pneumatic automation solutions. Contact us today to discuss your application needs and get the right vacuum suction cup solution for your industry.