Description

Product details

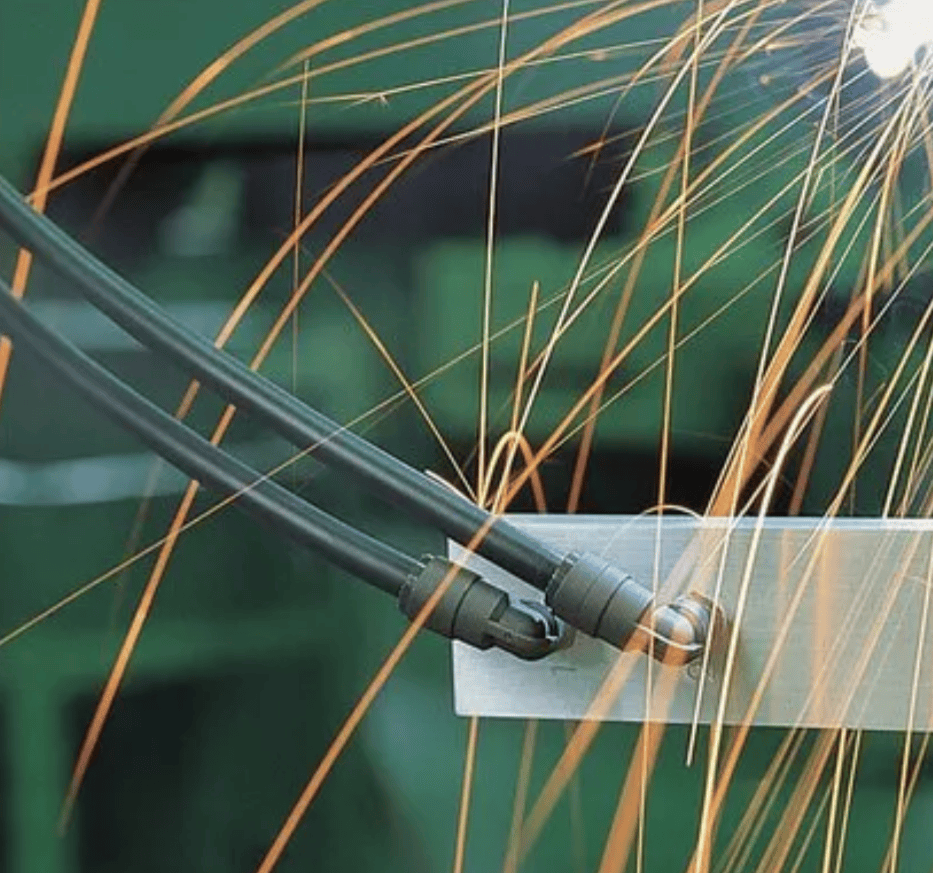

Vacuum Generators for Automation: A Complete Guide for Engineers Vacuum technology plays a vital role in modern automation, robotics, and material-handling systems. While vacuum suction cups are the visible gripping elements, the true driving force behind them is the vacuum generator. For engineers designing automated systems, understanding the types, performance factors, and integration of vacuum generators is essential for achieving reliable, efficient, and cost-effective solutions. This article provides a detailed EEAT-based guide to vacuum generators in automation, including their working principles, types, system components, and selection guidelines. 1. What is a Vacuum Generator? A vacuum generator is a device that creates negative pressure (vacuum) to enable suction-based gripping, lifting, and holding of workpieces. In automation, vacuum generators are integrated with suction cups, filters, tubing, and valves to form complete vacuum handling systems used across industries like: Automotive – sheet metal handling, windshield placement, and bumper assembly. Electronics – PCB handling, semiconductor wafers, and delicate components. Packaging – carton sealing, bag handling, and food-safe automation. Logistics – pick-and-place robotics for e-commerce and warehousing. 2. Types of Vacuum Generators Engineers have several options when selecting a vacuum source. Each type has unique advantages depending on application requirements. 2.1 Ejector-Based (Venturi) Vacuum Generators Working Principle: Uses compressed air through a venturi nozzle to create vacuum. Advantages: Compact, lightweight, low maintenance, fast response. Applications: Robotics, packaging, semiconductor handling. Considerations: Requires a reliable compressed air supply. 2.2 Vacuum Pumps Working Principle: Electrically driven pumps generate continuous vacuum. Advantages: High flow capacity, stable vacuum levels, energy-efficient for large systems. Applications: Automotive assembly, glass handling, woodworking. Considerations: Higher initial cost, requires regular maintenance. 2.3 Hybrid Systems Working Principle: Combine pumps with ejectors for specialized needs. Advantages: Flexibility, redundancy, optimized energy use. Applications: High-speed production lines with varied workpiece sizes. 3. Key Performance Factors for Engineers When selecting a vacuum generator, engineers should evaluate: Vacuum Level (kPa or inHg): Determines gripping strength. Flow Rate (L/min): Defines how quickly vacuum can be achieved. Response Time: Critical for high-speed pick-and-place automation. Energy Efficiency: Ejectors consume compressed air; pumps require electrical power. Noise & Heat Generation: Important for cleanrooms, labs, and operator safety. Maintenance Needs: Filters, seals, and moving parts must be serviced for long-term reliability. 4. Vacuum System Components A vacuum generator is only one part of the complete handling solution. For reliability, engineers must design systems with the following: Vacuum Suction Cups: Grip the workpiece (flat, bellows, oval types). Filters: Prevent dust, chips, or particles from reaching the generator. Tubing & Fittings: Ensure airtight connections and minimal leakage. Valves & Sensors: Provide control, feedback, and safety shut-offs. Manifolds: Distribute vacuum to multiple cups in synchronized systems. 5. Application Examples Electronics: Micro suction cups with ejector generators handle delicate wafers with minimal damage risk. Automotive: Centralized vacuum pump systems power multiple suction cups for handling large sheet metal panels. Food Industry: Hygienic vacuum generators paired with silicone suction cups ensure compliance with FDA and EU standards. 6. Best Practices for Engineers Match the generator type (ejector vs. pump) to production speed, part size, and available energy source. Always size the generator with margin for leakage and unexpected demand. Use inline filters close to suction cups for protection. Implement vacuum monitoring sensors for predictive maintenance and quality assurance. Consider modular vacuum systems for flexibility in future upgrades. 7. Conclusion Vacuum generators are the backbone of suction-based automation systems. By carefully selecting the right generator type, capacity, and system design, engineers can optimize efficiency, reduce downtime, and extend equipment life. Whether it’s compact ejector units for high-speed robotics or centralized vacuum pumps for heavy-duty handling, the right choice ensures smooth, reliable automation performance. Product details: vacuum generator, vacuum ejector, vacuum pump, automation gripping systems, pneumatic vacuum generator, Venturi vacuum ejector, vacuum handling automation, industrial vacuum systems.