Description

Product details

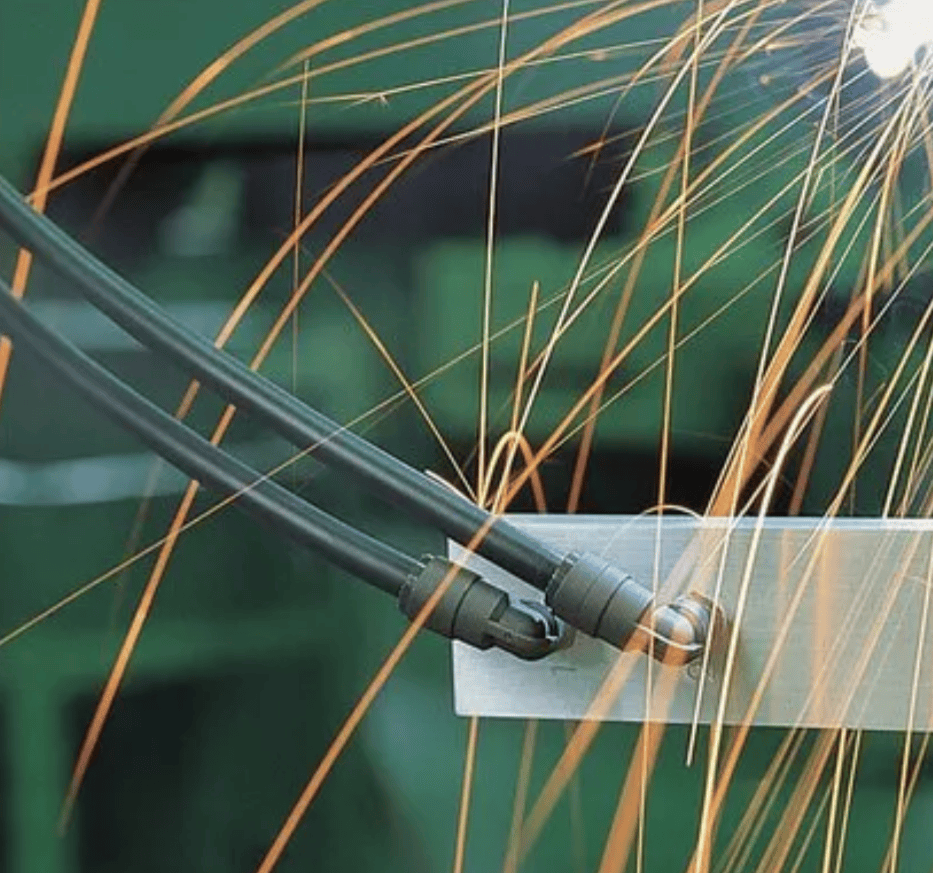

PU Tubes: High-Performance Pneumatic Solutions for Indian Industries Polyurethane (PU) tubes are a cornerstone in modern pneumatic systems, offering unmatched flexibility, durability, and chemical resistance. Used extensively in automation, assembly lines, robotics, and industrial machinery, PU tubes deliver reliability and precision, which are critical for high-efficiency production environments. For Indian engineers and industrial users, understanding material properties, design features, and applications is key to selecting the right PU tubing for your pneumatic systems. 1. Why Polyurethane Tubes? Polyurethane tubes stand out for their combination of flexibility, abrasion resistance, and chemical stability. Unlike PVC or rubber tubes, PU tubes can handle frequent bending, vibration, and high-pressure pneumatic flows without deformation. Key Advantages: High flexibility for tight bends and compact layouts. Exceptional wear resistance for long-term operation. Low friction coefficient for smooth pneumatic flow. Good chemical and oil resistance for industrial environments. Lightweight and easy to install in automation setups. These properties make PU tubes ideal for sectors such as automotive manufacturing, packaging, electronics assembly, and food processing. 2. PU Tube Material Properties Different PU tube formulations allow engineers to match tube characteristics to specific industrial requirements: Standard PU Tubes Properties: Flexible, lightweight, and suitable for general pneumatic applications. Temperature Range: -20°C to +60°C. Applications: Pneumatic conveyors, pick-and-place machinery, and air distribution systems. Food-Grade PU Tubes Properties: Non-toxic, FDA-compliant, and resistant to oils and grease. Temperature Range: -20°C to +80°C. Applications: Food and beverage processing, pharmaceutical packaging, and medical automation. High-Performance PU Tubes Properties: Extra abrasion resistance, higher pressure tolerance, and UV resistance. Temperature Range: -30°C to +90°C. Applications: Heavy-duty industrial machines, robotics, and automotive pneumatic lines. 3. Design Features and Options PU tubes are available in various sizes, colors, and wall thicknesses, giving engineers flexibility in system design: Internal Diameter (ID) & Outer Diameter (OD): Matches fittings and ensures optimal air flow. Color Coding: Facilitates system organization and easy maintenance. Reinforced PU Tubes: Added strength for high-pressure pneumatic systems. Pre-Cleaned or Clean-Room PU Tubes: Suitable for semiconductor, pharmaceutical, and medical device manufacturing. 4. Key Applications of PU Tubes in India PU tubing is widely adopted across Indian industries for efficiency, reliability, and safety: Automation and Robotics: Smooth pneumatic flow for actuators, cylinders, and grippers. Packaging Industry: Food-grade tubes for filling, sealing, and conveying applications. Automotive Manufacturing: Durable PU tubes for assembly line automation and air-powered tools. Pharmaceuticals & Medical Devices: Cleanroom-ready tubes for contamination-free pneumatic transport. 5. Integrating PU Tubes into Pneumatic Systems A PU tube is only as effective as the system it serves. A complete pneumatic setup includes: Fittings & Connectors: Push-in fittings for fast, leak-proof connections. Vacuum Generators & Pumps: Ensure steady air or vacuum flow. Filters & Regulators: Maintain clean, pressurized airflow for optimal performance. Manifolds & Tubing Networks: Organize distribution for multiple actuators or cylinders. By selecting the right tube size, material, and accessories, engineers can maximize system efficiency, reduce maintenance, and extend equipment life. 6. Conclusion PU tubes are a versatile, durable, and reliable solution for pneumatic systems in Indian industries. By understanding the material properties, design options, and proper system integration, engineers can achieve high efficiency, longevity, and safety in their automation and pneumatic applications. Investing in quality PU tubes ensures smooth operations, reduces downtime, and delivers cost-effective performance for years.